Seaweed Fiber Revolutionizes Garment Making

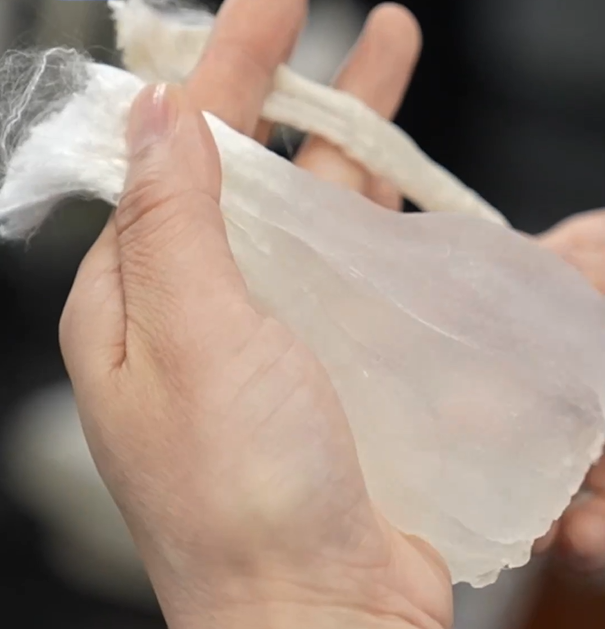

Qingdao University researchers show seaweed fibers. (PHOTO: SCREENSHOT)

By QI Liming

Researchers at Qingdao University have succeeded in extracting algin from seaweed to make seaweed fibers. Following an innovative breakthrough in technology, the seaweed fiber has been found to have self-extinguishing and low smoke output in fire situations, making it perfectly suitable for fireproof material.

Compared with the planting and extraction of traditional fiber materials such as cotton, flax, wool and silk, the extraction and processing of seaweed fiber can almost all be converted into various products, realizing the green, safe and environmentally friendly production concept.

At present, seaweed fiber can be used to spin yarn and weave cloth, and make a variety of colorful clothing after dying. The strength of seaweed fiber is 1.5 times that of traditional cotton, while the texture of the fiber is close to cashmere, which is very comfortable to the touch.

After nearly two decades' R&D, a mu (about 670m2) of sea area can produce four to eight tons of dry seaweed, which can be converted into one to two tons of seaweed fiber, and the fiber yield is three to six times that of a mu of cotton field.

To date, Qingdao already has the world's largest production line of seaweed fiber for textile and garment use, with an annual production capacity of 5,000 tons.